Industrial automation is no longer confined to futuristic factories, it’s the present reality transforming how businesses produce, assemble, and scale. From intelligent robotics to real-time monitoring systems, industrial automation solutions are streamlining everything from supply chains to safety compliance.

In fact, studies show that automated factories improve productivity by up to 30% and reduce operational costs by up to 20% (source: McKinsey). With demand surging for automation solutions for manufacturing, companies are investing in smarter, leaner operations powered by digital systems, sensors, and scalable control platforms.

But what is industrial automation, really? And how do modern businesses, from oil and gas to food production, leverage it to stay competitive?

This blog will break down the key types of industrial automation systems, how they work, the benefits they unlock, and how different industries are putting them to use. Whether you're upgrading legacy equipment or launching a fully automated factory solution, understanding this evolving field is crucial to future-proofing your operations.

What are Industrial Automation Solutions?

Industrial automation solutions refer to the integration of advanced control systems, machinery, and software technologies to streamline industrial processes with minimal human intervention.

These solutions leverage innovations like robotics, artificial intelligence (AI), sensors, and data analytics to improve the efficiency, accuracy, and scalability of manufacturing operations.

By automating repetitive tasks and optimizing production processes, these solutions help businesses increase productivity, reduce costs, and ensure higher quality control.

From automotive factories to food production lines, industrial automation is transforming the way industries operate, allowing companies to stay competitive and meet evolving market demands.

Businesses seeking the best automation software for digital transformation can find systems that integrate automation with analytics and data-driven decision-making tools.

Explore Our Web Design & Development Services!

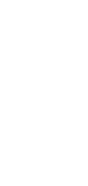

4 Types of Industrial Automation Systems

At its core, industrial automation refers to the use of control systems, such as computers, robots, and information technologies, to handle different processes in an industry with minimal human intervention. These systems are designed to improve accuracy, consistency, and efficiency.

There are four main types of industrial automation systems:

1. Fixed Automation (Hard Automation)

Ideal for high-volume production with low variability. It uses dedicated equipment to automate a set of operations, common in automotive assembly lines.

2. Programmable Automation

Allows changes in production configurations using software. It’s well-suited for batch production in industries like food and beverage.

3. Flexible Automation

Offers adaptability for product variation without significant equipment changes. Highly valuable in high-mix, low-volume manufacturing environments.

4. Integrated Automation

Encompasses complete process control, data analysis, and communication between machines, representing smart industrial automation.

These technologies work in harmony with automated control systems and data-driven decision-making platforms to optimize each phase of production. Thus, the Digital Transformation Services enable businesses in the Oil, Gas, and Renewables sector to modernize legacy systems and implement scalable, intelligent automation infrastructure, supported by an Oil and gas marketing agency to effectively promote these advanced solutions.

5 Key Technologies Powering Automation in Manufacturing

Modern industrial automation technologies combine hardware and software to improve operational efficiency and reduce error margins. Let’s look at some of the technologies driving change:

- PLC (Programmable Logic Controllers): Core control devices that automate electromechanical processes.

- SCADA Systems: Supervisory control and data acquisition for real-time monitoring and process control.

- IoT Sensors: Collect data from machines and environments to improve safety, predictive maintenance, and efficiency.

- Robotic Process Automation (RPA): Automates rule-based tasks and workflows, especially in repetitive administrative or manufacturing tasks.

- AI & Machine Learning: Analyze vast datasets from production lines for continuous optimization.

These tools form the backbone of any automated industrial system, especially as industries move toward digital industrial automation. The Web Design & Development Services integrate industrial dashboards and SCADA visualizations into web interfaces for real-time plant visibility in the Food and Beverage industry.

Explore Our Digital Transformation Services!

Top 5 Benefits of Industrial Automation for Modern Businesses

The impact of automation in manufacturing extends beyond reducing labor. It fundamentally changes how factories function, enabling them to be faster, more responsive, and more intelligent.

Here are the top benefits of investing in industrial automation engineering:

- Increased Productivity: Machines can operate 24/7 with minimal downtime.

- Enhanced Safety: Automated systems reduce the risk of accidents in hazardous environments.

- Improved Quality Control: Consistent production results in fewer defects and less waste.

- Cost Efficiency: Reducing reliance on manual labor lowers long-term operational costs.

- Real-Time Data Access: Integrated systems provide actionable insights for better decision-making.

These process automation solutions enable businesses to scale operations, stay competitive, and meet global demand without compromising quality or timelines.

Design Services help visualize complex automation data through user-friendly dashboards and interfaces tailored to the needs of sectors like Media and Entertainment, where rapid delivery and resource management are critical.

Real-World Use Cases of Industrial Automation

Let’s explore how different sectors are leveraging automation engineering solutions to gain operational advantages:

1. Automotive Manufacturing

Robotics, conveyor systems, and automated painting units are examples of automated process control in action. Assembly lines are optimized for both speed and precision.

2. Pharmaceuticals and Food Production

Automated industrial systems ensure consistent packaging, labeling, and quality inspection to meet regulatory requirements while maintaining scale.

3. Logistics and Warehousing

Smart conveyors, robotic picking systems, and automated storage increase efficiency in inventory management and order fulfillment.

4. Electronics and Semiconductors

Precision is paramount here. Automation technology in industry helps with micro-level placement, inspection, and testing.

Each of these applications highlights how businesses deploy custom industrial automation systems to meet their unique production goals. What is workflow automation in these industries? It refers to the integration of these systems, reducing manual steps and accelerating processes. SEO Services support industrial clients like those in the Technology sector to capture relevant leads actively searching for automation partners and digital solution providers.

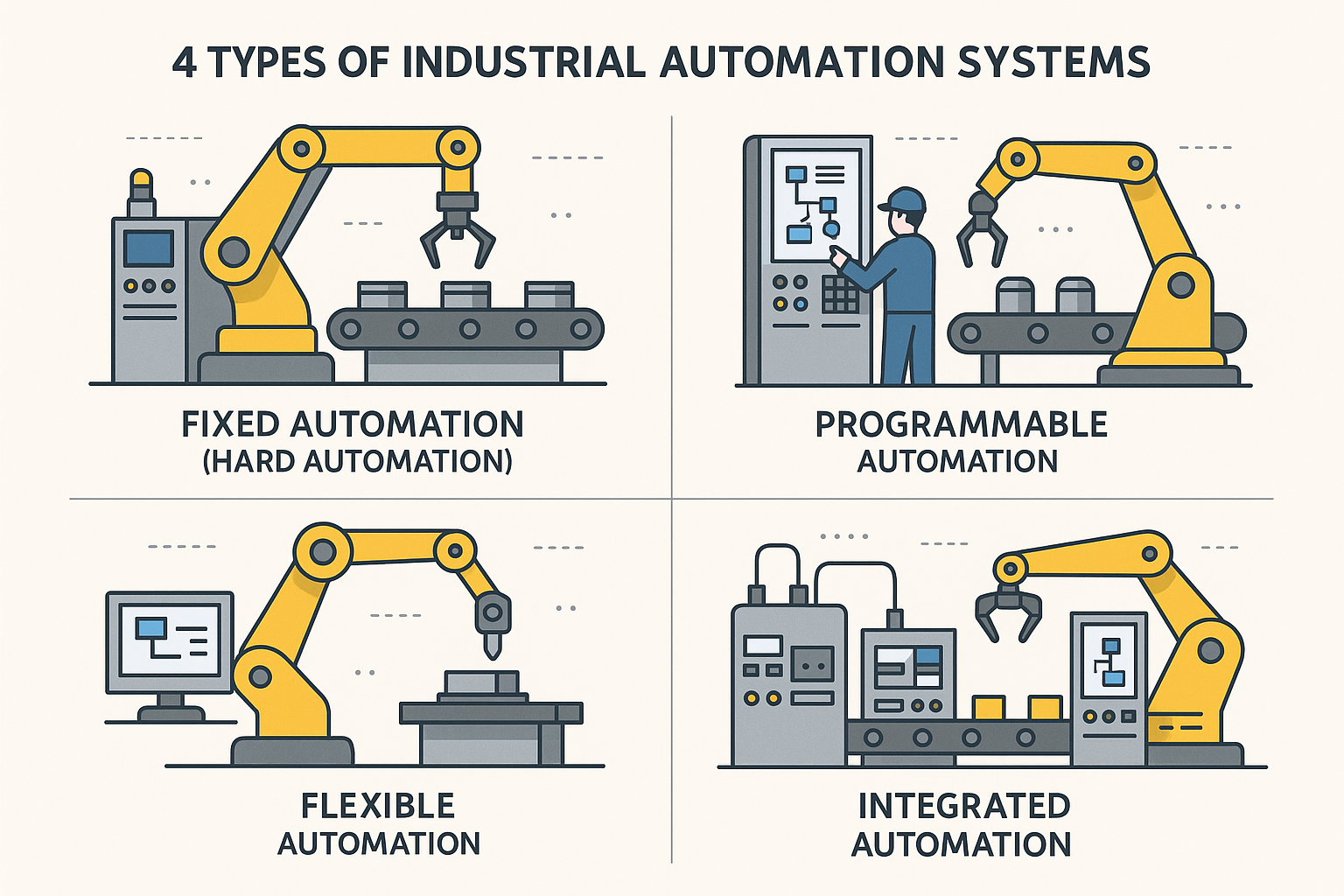

Implementation Challenges and How to Overcome Them?

While the advantages are clear, implementing industrial automation and control systems isn’t without challenges:

- Legacy Equipment: Older systems may not integrate easily with new platforms.

- Skill Gaps: Employees may need upskilling to manage or troubleshoot automated systems.

- Cost Barriers: Initial investment can be high, especially for SMEs.

- Change Management: Shifting from manual to automated operations requires cultural adaptation.

To address these, companies should conduct thorough needs assessments, invest in staff training, and choose scalable industrial automation platforms that allow gradual integration. SharePoint Consulting Services supports companies in regulated industries like Banking and Finance in organizing, tracking, and managing automation project documentation and compliance protocols.

The Future of Industrial Automation

The next wave of automation in industrial processes will be defined by smart, self-optimizing systems capable of learning and adapting over time. Emerging trends include:

- AI-Driven Predictive Maintenance: Minimizing downtime through data-led failure prediction.

- Edge Computing: Real-time data processing at the source for faster decisions.

- Human-Robot Collaboration: Cobots (collaborative robots) working alongside employees.

- Green Automation: Systems designed to reduce environmental impact.

As the future of industrial automation unfolds, businesses that adopt an integrated, digital-first mindset will be better positioned for long-term success.

The best website builders for small business are now incorporating automation features, making it easier for smaller companies to manage and grow their operations digitally.

Digital Marketing Services help automation-driven businesses reach B2B buyers with targeted content, case studies, and campaigns that position them as industry leaders.

FAQs: Industrial Automation Solutions

What is industrial automation?

Industrial automation refers to the use of control systems like computers and robots to handle industrial processes with minimal human intervention.

What are the main types of industrial automation systems?

There are four main types: fixed automation, programmable automation, flexible automation, and integrated automation.

How do automation solutions benefit manufacturing?

They increase productivity, reduce labor costs, improve safety, and enhance quality through consistent, repeatable processes.

Which industries benefit most from industrial automation technologies?

Industries such as automotive, food and beverage, oil and gas, electronics, and logistics benefit significantly from automation.

What challenges come with implementing industrial automation?

Common challenges include integrating legacy equipment, training staff, managing costs, and adapting company culture to automation-driven workflows.

Conclusion

Whether you’re looking to reduce errors, lower production costs, or meet increasing demand, industrial automation solutions offer the tools to get there, faster and more efficiently. By combining sensors, software, and smart systems, companies can build scalable operations that are agile, competitive, and ready for the future.

Centric helps organizations navigate the shift to automation through customized strategies and digital solutions. Explore our B2B Marketing Services to support your automation journey with tailored communication, content, and lead generation strategies that resonate with decision-makers in technical industries.